Foundations of Efficient Tool Storage Systems

Efficient tool storage is the backbone of any high-performing workshop, directly impacting productivity and safety. Disorganized tools waste up to 20 minutes per hour and increase accident risks. A well-structured system ensures every item has a designated, easily accessible place.

Consider workshop dimensions, tool inventory size/type, and mobility needs. Portable tool chests suit dynamic workspaces, while fixed cabinets optimize static stations. Steel or aluminum cabinets handle heavy tools, while polymer solutions work for lighter instruments. Lockable compartments add security.

A solid foundation reduces search time by 30%, prevents misplacement, and prolongs tool lifespan. It also sets the stage for advanced solutions like vertical storage or digital tracking.

Key elements:

- Align with workshop layout

- Match material durability to tool weight

- Balance accessibility and proximity

- Include theft and moisture protection

- Plan for future scalability

Tool Storage Revolution Through Labeling & Categorization

Proper organization slashes tool retrieval time by up to 70% (Industrial Efficiency Review 2023). Structured storage reduces workflow interruptions and cuts replacement costs.

Color-Coding for Instant Identification

Color systems create visual mapping—red for electrical tools, blue for measurement devices. Fabrication shops report 50% faster tool returns using color-coded silhouettes or foam cutouts. Missing tools stand out, improving safety.

Digital Inventory Tracking

Barcode and RFID cabinets track tool use in real-time. Automated alerts prevent shortages, and usage data reveals optimization opportunities. Industrial settings see less than 2% equipment loss with these systems.

Vertical Tool Storage Solutions Maximizing Workshop Space

Wall and ceiling storage increases usable space by 30% and speeds up retrieval (Workspace Efficiency Journal 2023).

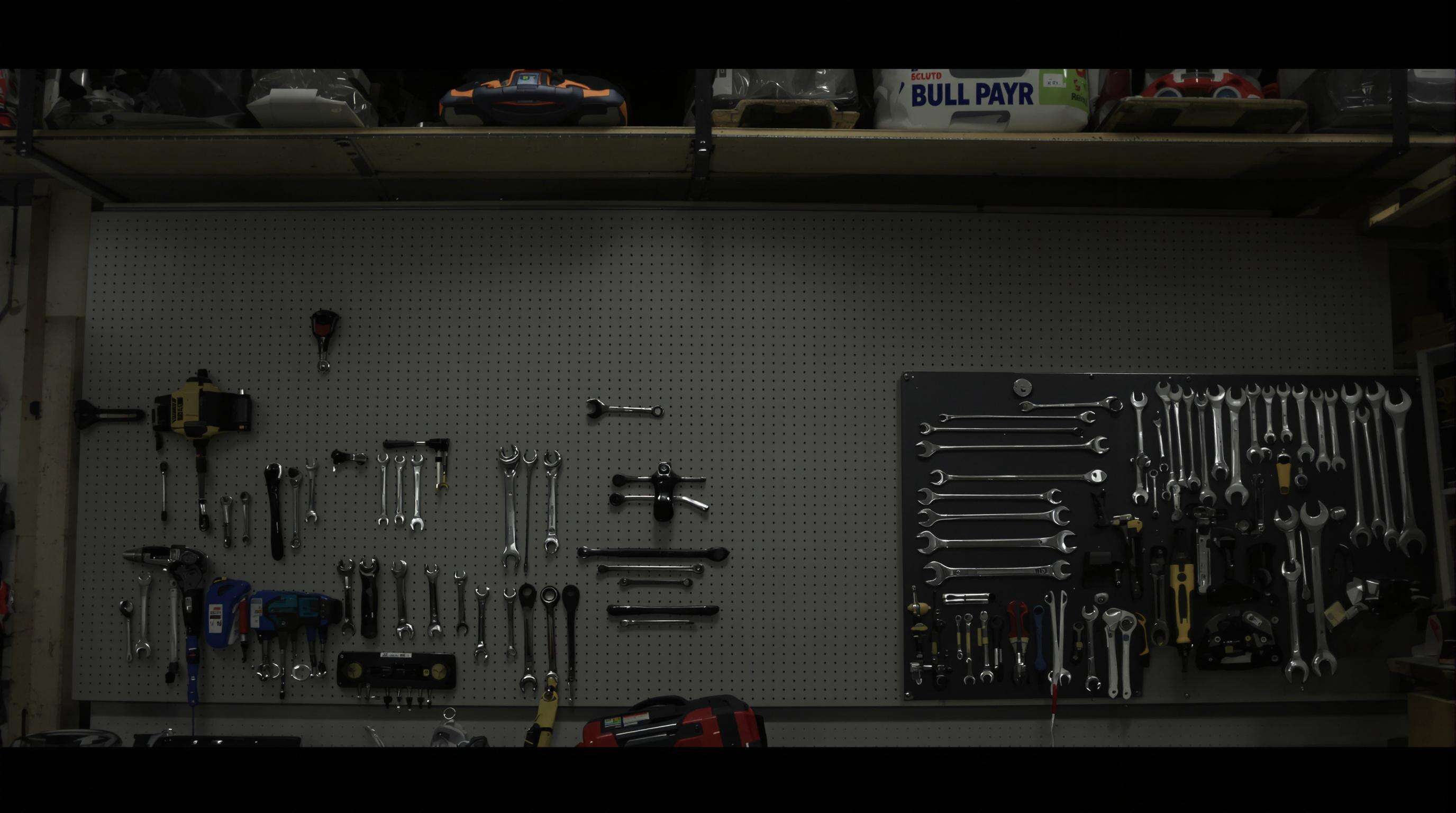

Pegboard Configurations

Adjustable hooks and shelves allow easy reorganization—ideal for multi-project workshops. Color-zoned layouts save 7-9 minutes daily (Workshop Management Review 2023).

Magnetic Strips

Industrial strips support over 50 lbs per foot, securing wrenches and welding tools. Slim and hardware-free, they enable one-handed access during critical tasks.

Overhead Racks

Ceiling-mounted racks free up 40% of floor space (Industrial Space Utilization Report 2023). Pulley systems make bulky or seasonal items accessible when needed.

Workflow-Optimized Tool Storage Zones

Strategic zones cut retrieval time by 19% (Workshop Efficiency Institute 2023).

Mobile Charging Stations

Carts with modular battery slots and integrated charging ports reduce fire risks by 32% versus DIY setups.

Ergonomic Storage Heights

Storing frequently used tools between 28"–44" reduces back strain by 41% (OSHA 2023) and speeds up projects by 22%.

Dedicated Sharpening Stations

Centralized hubs with diamond plates and microfiber-lined drawers extend tool lifespans by 18% (Tool Maintenance Quarterly 2024).

Maintenance Protocols for Sustainable Tool Storage

Daily wipe-downs and monthly deep cleaning prevent dust buildup. Biannual lubrication reduces wear on high-cycle components. Humidity sensors alert when levels exceed 40%, preventing corrosion.

Climate-Controlled Cabinets

Precision tools require humidity between 40-60% and temperatures of 64–73°F to avoid calibration errors. Non-conductive shelves protect sensitive electronics.

Industrial-Grade Tool Storage Trends

Advanced systems now offer AI-assisted inventory, cutting retrieval time by 43% (Material Handling Institute 2023).

RFID-Enabled Tool Chests

Automated tracking reduces inventory discrepancies by 37% while predicting maintenance needs. Payback typically occurs within 14 months through productivity gains.

FAQ

Why is efficient tool storage important?

Efficient tool storage improves workshop productivity and safety by reducing search time and preventing tool misplacement.

What are the benefits of color-coding tools?

Color-coding helps in instant identification, faster tool retrieval, and improves safety by making missing tools stand out.

How does vertical storage optimize workshop space?

Vertical storage solutions like pegboards, magnetic strips, and overhead racks increase usable space and speed up tool retrieval.

Why should tools be stored at ergonomic heights?

Storing tools at ergonomic heights reduces back strain and speeds up projects by providing easy access to frequently used items.

What does digital inventory tracking offer?

Digital inventory tracking provides real-time tool usage data, prevents shortages, and minimizes equipment loss, enhancing productivity.